What Makes ISO 9001 / AS9100 Certifications So Important?

By Crystal Fuller, ISO 9001 Internal Auditor

Director, Manufacturing & Logistics | BAC

In a world driven by precision, quality, and accountability, certifications such as ISO 9001 and AS9100 are more than just plaques on the wall; they are a commitment to excellence. For manufacturers and suppliers serving both government and commercial sectors, these certifications serve as a tangible demonstration that systems are in place to consistently meet customer and regulatory requirements while striving for continual improvement.

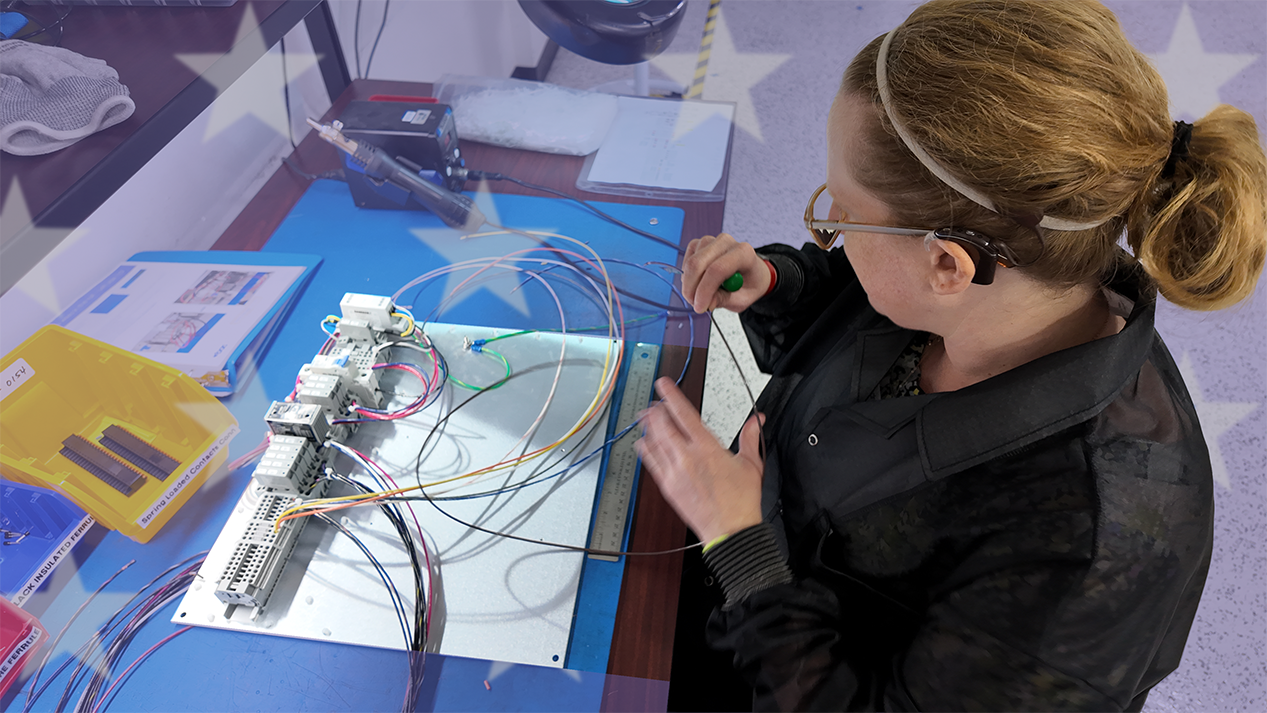

At BAC, ISO 9001 and AS9100 certifications define how we operate. They’re what make every process, from the first crimp to final inspection, consistent, traceable, and reliable for every customer we serve.

ISO 9001: The Foundation of Quality Management

ISO 9001 is the world’s most recognized Quality Management System (QMS) standard, developed by the International Organization for Standardization (ISO). It provides a framework for organizations to consistently deliver products and services that meet customer expectations and regulatory requirements.

Key principles of ISO 9001 include:

- Customer Focus: Putting customer needs at the center of every decision.

- Leadership: Creating clarity of purpose and accountability at all levels.

- Engagement of People: Creating clarity of purpose and accountability at all levels.

- Process Approach: Understanding that no task stands alone; every process connects to the next.

- Improvement: Treating each project as a chance to refine, not just repeat.

- Evidence-Based Decision Making: Using data, not assumptions, to guide actions.

- Relationship Management: Building long-term trust with suppliers and partners.

AS9100: Aerospace Quality at Its Highest Standard

AS9100 builds upon ISO 9001 with additional requirements designed for the aerospace, defense, and aviation industries fields where precision isn’t optional, and the margin for error is virtually zero. The standard expands on core quality principles to include risk management, product safety, configuration control, and counterfeit part prevention, ensuring reliability and accountability across the entire supply chain.

For BAC, AS9100 isn’t just about meeting aerospace expectations; it’s about applying that same level of rigor to everything we produce. Whether we’re assembling cables or packaging components, the discipline of AS9100 demands keeps our processes consistent, our documentation transparent, and our customers confident.

Organizations certified to AS9100 demonstrate that they:

- Deliver products and services that meet the most demanding industry standards.

- Maintain full traceability of materials, documentation, and test results.

- Apply process discipline and risk-based thinking at every step of production.

- Participate in OASIS, the global aerospace quality database that provides transparency to customers worldwide.

Why These Certifications Matter

- Quality You Can Verify

Quality isn’t just a claim; it’s something you can prove. Every process at BAC is audited by independent, accredited professionals who evaluate how we purchase materials, produce assemblies, correct issues, and review results. Our customers can trust not only what we deliver, but how we deliver it.

- A Ticket to Compete in Aerospace and Federal Markets

Many government and aerospace contracts don’t just prefer ISO 9001 or AS9100; they require it. These certifications show that BAC can meet the same high standards expected of larger, prime contractors. It’s how we earn a seat at the table, compete for complex work, and build confidence across every link in the supply chain.

- Continuous Improvement That Never stops

Certification isn’t a one-time achievement; it’s a discipline. Internal audits, management reviews, and data tracking keep us improving every day. We don’t just maintain compliance; we find better ways to work, communicate, and build quality into every process.

- Traceability You Can Trust

In manufacturing, precision and accountability aren’t optional; they’re the foundation of trust. ISO 9001 and AS9100 require full traceability for every job we take on, whether that’s a cable assembly, a packaging project, or a multi-component build. Each material, supplier, and process step is documented, verified, and linked back to its source. This level of control protects our customers, our reputation, and the integrity of every product that leaves our floor.

- Customer Confidence

Certification reflects a mature, verified system of checks and balances that minimizes variability and errors. For customers, it’s assurance that every BAC product, whether assembled, packaged, or shipped, is built with integrity, precision, and full accountability from design to delivery.

At BAC, these standards go beyond compliance; they define how we work. Standardized workflows ensure consistency across teams and shifts. Regular training and internal auditing give employees the tools to build both technical and leadership skills. Every assembly or shipment is backed by data-driven verification and lean, efficient processes that protect quality and strengthen customer trust.

For customers, it means confidence. For employees, it means pride. r At BAC, Quality is not just a standard—it’s our signature.

About the Author

Crystal Fuller, ISO 9001 Internal Auditor

Director, Manufacturing & Logistics, BAC

Crystal Fuller leads BAC’s Manufacturing & Logistics division, where precision, quality, and purpose intersect. With extensive experience in quality assurance and operational leadership, she has guided BAC through ISO 9001 and AS9100 certification, strengthening its position as a trusted partner to federal, state, and commercial customers. Under her direction, the 10,000-square-foot facility delivers cable assemblies, 3PL fulfillment, and light manufacturing services, all grounded in process discipline, traceability, and a culture of continuous improvement.

Celebrating Value, Talent and 27 Years of Dedication: James Fox Shines During NDEAM

Celebrating Value, Talent and 27 Years of Dedication: James Fox Shines During NDEAM National Disability Employment Awareness MonthOctober is National...

Did you know? BAC Maintains Over 10 Million Square Feet of Federal Facilities

Did you know? BAC Maintains Over 10 Million Square Feet of Federal FacilitiesBenny Lenett operating a floor machine at Kennedy Space CenterBy Rich Hurtado,...

NDEAM Employee Spotlight: Gerald D.

Meet Gerald Davis: Celebrating Value and Talent at Fort Bragg National Disability Employment Awareness MonthThis October, in honor of National Disability...